At DRUPA, Baldwin will launch a portfolio of three new products for the Flexo market: FlexoDry2, the new ultra-efficient Infra-Red and Hot Air dryer; Flexo Cleaner Brush, the new industry standard for automatic cleaning and drying of printing plates in Flexo printing; and FlexoCleanPick, that removes hickies without stopping the press.

FlexoDry2 – Ultra-efficient Dryer to Reduce Power Consumption

Baldwin’s FlexoDry2 dryer is specifically developed for Corrugated Flexo printing presses and reduces electrical power consumption by up to 30 percent over traditional IR dryers, using patented Diamond IR lamps utilizing special ceramic reflectors to focus intense IR radiation. The FlexoDry2 system offers an integrated hot air knife to scrub any moisture off the surface of the ink and coating, delivering state-of-the-art performance for high-speed multicolor applications.

Safety being paramount throughout the design, the FlexoDry2 dryer comes with an integrated light curtain as standard and an optional Camera Vision System. Multiple light beams increase lamp head coverage and improve safety through the use of linear transmitters.

The company also offers conventional and LED UV for Corrugated Flexo printing.

Flexo Cleaner Brush – Automatic Cleaning and Drying of Printing Plates

The Flexo Cleaner Brush cleaning system automatically cleans and dries printing plates within three to four minutes, creating a cleaner environment, reducing skin contact with inks and solvents as well as minimizing operator contact with moving parts and nip points. Plate cleaning is done without de-coupling the press, improving operator safety. Afterwards the plates can be stored on the shelf or the current print job can be started again.

Baldwin’s Flexo Cleaner Brush system is designed to completely eliminate substrate fiber accumulation, to avoid negative impact on the print image quality. The system allows for printers to obtain optimal print quality results with minimal downtime, with no need for manual rewashing and drying.

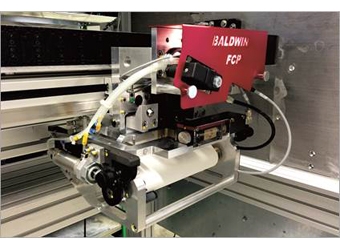

FlexoCleanPick – Removes Hickies with a Kiss, Without Stopping the Press

The FlexoCleanPick solution is a system that consists of a traversing cloth wash head that picks up hickies and fibers from the Flexo plates during the printing. Different cleaning modes are available such as; spot cleaning, constant cleaning or intensive cleaning that cleans the plates during the print. With a dry cloth, the system is kiss touching the plate and picks up the hickies off the plate without the need to stop the press, enhancing quality and productivity without creating waste. With a wetted cloth, the system can even perform a deeper cleaning of the plates if required.

Peter Hultberg, Chief Commercial Officer at Baldwin, comments, “We are very proud to offer our new, advanced Flexo Printing portfolio to Flexo corrugated printers around the world. These products based on Baldwin’s high-tech Cleaning and IR Drying product portfolios will further unlock potential for our customers, as they continue to develop their production performance and quality of print.

“We are excited with the feedback we have received from the customers that already have taken advantage of our technology.”

For more information, visit www.baldwintech.com.