The variety and volumes of digitally produced signs and displays continues to grow, whereas wide format companies often are not ready to efficiently handle that growth. Typical wide format workflows and finishing operations can be inefficient and unprofitable when tools and processes are not optimized. Too many manual steps, equipment setup times, incorrect material handling, and lack of controlling a workflow are all impeding print providers from being successful.

Esko (www.esko.com) at booth #954 during SGIA Expo 2016, September 14-16, in Las Vegas will demonstrate a series of innovations launched just two months ago at drupa, to help companies get the most out of their workflows, their equipment, and their staffs.

“Esko is in a unique position to introduce new efficiencies to the wide format graphics workplace,” explains Stephen Bennett, Esko Vice President, Vice President of Sales at Esko. “At SGIA, we will demonstrate a range of innovations to our digital cutting workflow and Kongsberg tables that focuses on removing non-value-added time from the production process. We put solid operational control and management tools in the hands of our customers and set a new industry benchmark for Overall Equipment Effectiveness.

“These innovations help operators to spend up to 30 percent less time in job preparation, and to be ready for the next job 25 percent faster. Our integrated systems are unique among vendors—they employ both workflow software as well as Kongsberg finishing tables, delivering overall equipment productivity increases of 10 percent or more.”

New: Wide Format Workflow Software Boosts Production Throughput

Featured at SGIA will be Automation Engine Avant, a new, dedicated wide format workflow software bundle that contains wide format workflow automation including preflighting, file editing, adding cutting paths, and optimal nesting on a sheet. Automation Engine Avant creates productive workflows that increases throughput on digital printers and digital finishing platforms, while enhancing file management and communication to customers.

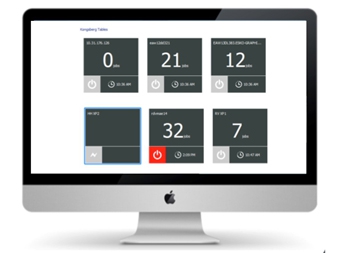

The Avant bundles with Esko’s new Device Manager. This software is used to communicate job status and help to manage jobs based on cutting time and material. Precise production planning and prioritization of digital finishing jobs becomes easier to manage. Operators can prioritize table queues, insert rush jobs and balance workloads between different tables, even at different sites. With the new Estimating software module within Esko Device Manager, better job quotes and accurate forecasts are easy. Automation Engine Avant is a unique lever to optimize wide format production, from design to delivery.

Designing Signs and Displays Simplified

Also on display will be Esko’s powerful structural design software, ArtiosCAD, the ideal product for all P-O-P, P-O-S, and freestanding display designers. The newly released ArtiosCAD Display Store (www.esko.com/en/lp/artioscaddisplays/) makes designing attractive displays possible for everyone, and gives printers quick access to new designs.

To improve graphics editing of signs and displays, Esko has partnered with CHILI Publish to offer online editing. With this solution, on display at the Esko booth, the artwork creator can enable anyone in the supply chain to modify packaging content within established constraints.

Simplified Kongsberg Platform Choice—and a Reduction of Waiting Time Between Jobs

Typical finishing operations suffer because their equipment is not used optimally: there are too many manual steps; setting up cutting tables takes too long; and prioritizing jobs as well as optimized material handling is not always possible.

Esko has streamlined and improved its Kongsberg table portfolio to help customers more easily identify the systems that best suit their needs. They can choose from two primary families—the greatest flexibility for versatile and creative jobs (Kongsberg X), or the best productivity for efficient production runs (Kongsberg C). On display at SGIA on display will be Kongsberg X24 and Kongsberg C64 finishing tables.

On these tables visitors at SGIA can see demonstrations of following innovations:

* Multizone production lets operators divide the surface of the Kongsberg table into two or more zones. While the table head is working on one zone, an operator can use the other zone to clear the finished piece and load a new sheet. This allows the machine to operate continuously without waiting. The new Auto Tool Adjust on Kongsberg tables uses camera inspection and digital image processing to make sure knife blades and router bits are still sharp and correctly installed. Operators get feedback on set-up or replacing of the bits and blades.

* Driving a Kongsberg table will be the newly introduced Kongsberg i-BF board feeder—one of a family of high-capacity sheet feeders for the Kongsberg tables. It feeds corrugated, paper core boards, and plastics quickly and accurately from pallets. It is indispensable for the automation of all applications that require medium to high run lengths of rigid materials.

“With our integrated soft- and hardware innovations, Esko closely aligns the performance of digital finishing operations and prepress workflows with the faster digital presses, effectively eliminating an important bottleneck,” concludes Bennett. “We simplify the workflow process for sign and display facilities—or as we say, ‘Sign and Display Simplified.’”

For more information, visit www.esko.com.