Show sponsor Esko will be featuring ways to automate workflows on booth #3307 during Graphics Canada, Canada’s largest graphics & printing exhibition, on April 16-18, 2015, Toronto International Centre. Celebrating more than fifty years as Canada’s national graphics and printing show, Graphics Canada features innovations, products and services from more than 200 industry suppliers.

“One of the keys to success as a print provider–whether sign & display, packaging, or commercial print–is production efficiency, which is often delivered by automation. Esko Automation Engine is taking hold among many Esko customers to make prepress production much easier and to help connect production to business and web to print services,” remarks Marc Raad, Esko Account Manager, Canada. “At Graphics Canada, we will be focusing on automation, package printing, and sign & display printing, which is prospering in Canada. Many print providers have installed Esko Kongsberg digital finishing tables over the past year. We will be displaying a larger Kongsberg XP 24 table, which provides a short run production capabilities, 24/7.”

Automation Engine: At the heart of prepress production

Automation Engine is a modular workflow server with dynamic workflows that are easy to set up and operate. It ensures increased efficiency and throughput and saves time and money. It is, by all standards, an exceptional answer to the daily challenges of print professionals who need to increase quality, reduce errors and drive cost out of the process. Automation Engine enables unparalleled workflow automation with rock-solid quality control.

Automation Engine takes the errors out of the process by allowing users to preset repetitive tasks and make automated decisions within the workflow. When operator interaction is required to ensure quality, the comprehensive checkpoint in the workflow allows for easy access. In addition, interfaces between order administrative systems (MIS or ERP) and prepress production further reduce the manual interaction. Using database driven job management, Automation Engine serves as the heart of any size prepress production operation.

With a transparent user interface, operators, customer service representatives or administration departments can easily interact with the workflow, and with its extensive conditional automation capabilities.

Suite 14 software portfolio offers workflow tools for a complete range of print applications

Automation Engine is one piece of Esko Suite 14, an update of the world’s most complete collection of preproduction software tools for packaging and signage and display production. It supports and manages the packaging and print processes for brand owners, retailers, designers, packaging manufacturers and print service providers. While the wide range of design, prepress and workflow applications will be on display, Esko will focus on solutions for wide format printing:

ArtiosCAD is the ideal product for all corrugated, folding carton and POP/display designers. More and more companies are also investing in ArtiosCAD for structural display design. ArtiosCAD’s extensive library of resizable display designs helps designers so they don’t have to design new displays form scratch.

Even in today’s digital world, the majority of packaging teams work with traditional methods of communication, such as phone, email and ftp. This way of working leaves little room for innovation and typically adds time to the process through lack of visibility into critical paths. It’s also very hard to track the project’s status within the many outsourced suppliers in the process. WebCenter connects all stakeholders in the process and brings clarity to this process with a centralized project management and communication system.

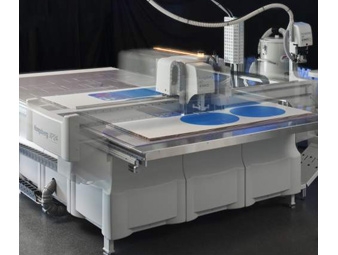

Kongsberg XP24 finishing table

The Kongsberg XP24 finishing table, made for handling the combination of corrugated board and other rigid or roll materials used in POP products and product displays, offers exceptional productivity and throughput. It helps turn short-run POP/POS displays work into profitable, value added jobs, helping sign and display shops offer their customers on-demand production, 24/7, with just-in-time delivery. Even with a maximum speed of 66″ inches per second, the seamless workflow no longer requires an operator to restack or transfer materials. An optional conveyor extension can work with rolls or sheets/boards with an Auto-Feeder with scissor-lift and transfer cart system, expanding the quantity of print runs that can be pre-stacked. i-cut Vision Pro registers the actual dimensions and positions on the printed result to assure finishing is adapted to the graphic’s shape. An extensive array of available tools matches the wide range of materials that can be used.

i-cut Suite: Software to power the design to print to cut workflow

i-cut Suite software lets sign & display companies streamline their workflows. It preflights and edits incoming PDF files, and helps build and edit sheet layouts, ensuring that jobs make the optimum use of substrates through intelligent true shape nesting and tiling. Kongsberg table technology ensures that die-less cutting contours match printed images perfectly, registering the actual dimensions and positioning cuts on the printed result. With i-cut Automate, all of these functions are automated in a single workflow, with less operator intervention. In a more commoditized market, sign & display shops are also realizing that unique 3D display projects offer higher margins.

“Esko is proud that our presence has extended in recent years in Canada, not only with many new installations nation-wide, but also at events like Graphics Canada,” adds Raad. “We look forward to greeting our customers, and making new friends at booth 3307.”