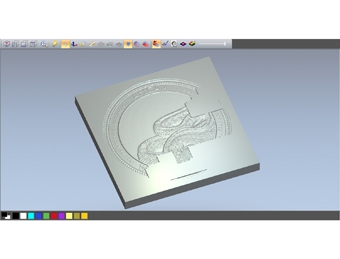

The 2015 R2 version of Delcam’s ArtCAM Pro artistic CADCAM will be featured at ISA Sign Expo on Booth #723 from April 21, 23, 2016 at the Orange County Convention Center. The software features improvements in design and machining, including the ability to create support structures for 3D Printing, easier designing with vectors, more design options with real-time updating, and faster machining simulations.

See full details on the new release at http://www.artcam.com/pro/latest-version.asp.

Unlike most other CADCAM systems, ArtCAM Pro is aimed at skilled artisans rather than engineers and requires much less knowledge of engineering or computing. It has been particularly successful in the sign making industry to increase productivity, improve quality and deliver new designs more quickly.

The main enhancement for the new version of ArtCAM Pro is the ability to create support structures for 3D Printing. Users can generate intelligent support structures, either manually or automatically, and can also use batch assembly for the printing of multiple items. 3D Printing offers ArtCAM users an alternative route to machining for the production of complex models.

The range of modeling tools that operate in real time has been extended to include the ability to create smooth domed shapes or domes with a centerline ridge, and the option to make intricate weaves. Real-time operation makes it easier to create exactly the effect that is required and shortens design times.

The main machining enhancement in the new release is significantly faster machining simulations thanks to a new algorithm that uses the specialist processor in modern graphics cards to calculate multiple operations simultaneously. This gives major benefits over standard multi-threading.

Another area of improvement is corner machining, where fillets can be added to vectors to allow more accurate machining of slots. In a related development, loops can be added for creating corners with knife cutting.

Finally two new options are available in the 3D offset strategy. Firstly it is now possible to spiral from the outside in or from the centee outwards. The strategy can reduce tool wear and give better surface finish. Secondly on-surface links can be used. This reduces the number of plunge and retract moves and so saves machining time.