A new DTF Powder-to-Film system uniformly coats DTF films with adhesive powder, improving DTF printing performance and operator safety, it was announced by Mark Vasilantone, president of Vastex International.

“Until recently, most shops doing DTF have been hand-coating the films using open plastic containers that expose shop personnel to adhesive dust and require operator time and attention to obtain reliable results,” says Vasilantone. “The Vastex system provides uniform coverage without dusting and spillage, reducing waste and freeing staff to optimize production time.”

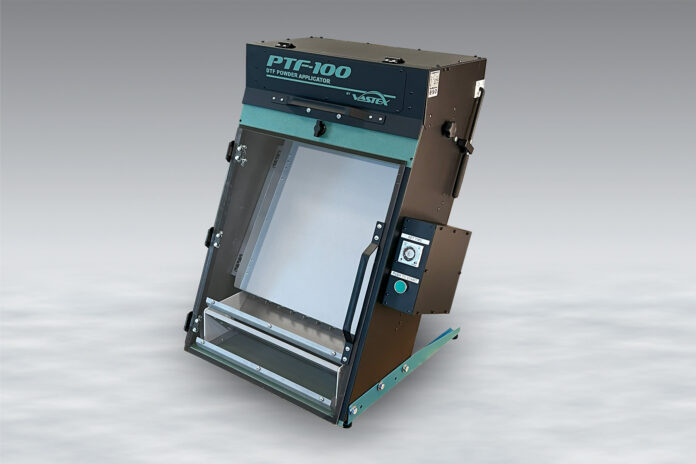

The PTF-100 consists of a steel case on a stand, with a clear polycarbonate door set at an angle. It comes with two identical cartridges, each of which can hold approximately 3 lbs (1.4 kg) of adhesive powder.

To operate, a filled cartridge is inserted at the top of the unit, and an empty cartridge at the bottom. An operator positions the wet DTF printed film on the application tray, print side up. Once the polycarbonate door is closed tightly, the operator can adjust the angle of the powder deflector and the amount of powder to be released.

With each cycle, the user pulls a lever to release the desired amount of powder, then pushes it to start the timer/vibration. The top cartridge releases adhesive powder which rains down on the film, ensuring complete and even coverage. When empty, the upper cartridge can be switched quickly and cleanly with the lower cartridge containing all excess powder, reducing exposure while eliminating waste and allowing continuous production until refilling is needed.

Made in the USA, the PDF-100 can accommodate film sizes up to 16 x 20 in. (406 to 508 mm), and features an adjustable timer for repeatable results.

Purpose-built for DTF printing, the unit can sit on the Vastex S1-27 stand with drawer kit for storage of film and extra powder. It pairs well with Vastex D-100 or D-1000 tabletop conveyor dryers equipped with rear-mounted powered exhaust hood to vent glycol fumes away from the shop environment. Vastex also offers heat presses and sturdy mobile utility stands that can hold most DTF equipment to optimize the shop floor layout.

The company also manufactures other specialized infrared conveyor dryers for direct-to-film, direct-to-garment, and screen printing applications, as well as manual screen printing presses, athletic numbering systems, flash cure units, screen exposing units, screen drying cabinets and washout booths, and offers a comprehensive range of training classes for entry level, intermediate and advanced screen printers.