The 2025 Top Young Sign Makers are comprised of sign industry professionals who have displayed their design prowess, project management skills, installation techniques, sales ability and more. With winners spanning from Boston to Fort Worth, Texas, they’ve made their mark on the nation’s signage industry landscape. As you’ll soon find out after meeting this year’s winners, managing a sign package installation project for an apartment building, public space or corporate headquarters can take months of preparation, pallets and pallets of materials, weeks of training and the ability to adapt and overcome obstacles.

These winners, who were all under 40 for the entirety of 2024, have shown promise in their young careers in signage and the ability to overcome adversity and rise up the ranks of their shop. The gold medal winner, Peyton Westrum of Cowtown Graphics & Signs in Fort Worth, Texas, had her title of Client Success Manager custom made by her shop’s owner due to the dynamic and successful work she did throughout her eight years at the company. Ian Fernandez, the silver medalist, is an extremely talented project specialist who puts his touch on nearly element of his projects for Bluebird Graphic Solutions in Woburn, Massachusetts.

Fernandez, an immigrant from Cuba, is proud of his roots and happy to put his talents to work for Bluebird, which is a registered Minority Business Enterprise as a part of Massachusetts’s Supplier Diversity Office. SBI would like to thank all of those who took the time to nominate for the 2025 awards, there were some very inspiring stories across the board, and as always, it was difficult to whittle it down to just five winners. Continue reading to meet the 2025 winners!

Gold

Peyton Westrum – Client Success Manager

Peyton Westrum – Client Success Manager

Cowtown Graphics & Signs

Peyton Westrum, 29, has packed a lifetime of signage work into the first decade of her impressive career. The Client Success Manager for Cowtown Graphics & Signs leads the Fort Worth, Tx.-based shop on large, complex projects that leave their mark on the city they call home. Take their work at the T&P Station, a train station terminal in Fort Worth that recently underwent a $1.75 million renovation that included new wayfinding signage, monument signage and historic art exhibits, among other things. Working closely with RSM Design, The Fain Group Construction, Trinity Metro and Downtown Fort Worth, Inc., Peyton and her team spent weeks creating a competitive quote for the job, which was awarded to them after a few months of deliberation. After winning the bid, they got to work immediately, creating a smaller version of all of their proposed installations for the station to analyze before the real work began.

“So we had to do an actual mock up for each sign type. And they weren’t all full size. So, for the big channel letters we did a smaller version of them,” says Westrum. “We actually built it all out and they all came over to our shop and looked at everything. We talked about what they liked, what they didn’t like and what kind of changes were going to be needed. So, we did a couple of rounds of the mockups. I think it probably took three rounds to get everything where they liked it. It was beautiful. And they finally gave us the go ahead.”

After that, it was time for the hard work and innovation. One of the most innovative aspects of the install involved the large “T&P Station” channel letters that were to be installed outside the station. In order to achieve the industrial look that the client wanted, Cowtown decided on a unique solution to fill put the giant letters.

“I think the biggest channel letter was five feet and three inches tall. They’re metal letters, but we put concrete in the face and on the back of them. So, it was about an inch to two inches of concrete inside the channel letters,” she says. “And the whole process of making this was really very cool and interesting. It was a little bit different than a regular set of channel letters. So, we had to put some chicken wire in the faces and the backs, then we put the concrete inside. Our team came up with this neat little trick to get all the concrete settled. They poured it in there, and it was hard at first to get it all smoothed out and level. Well, they came up with this little technique where they got a jackhammer and used the vibrations to spread all that concrete out evenly, it was super awesome.”

These type of ideas and dynamic decisions are what separate Westrum and Cowtown from the competition. She’s been with the company for eight years, immediately proving her worth and moving up the ladder at a fast pace.

“Before I came here, I had two years of experience with another sign company and all I did there was office administration and permitting stuff. So, I didn’t have a whole lot of knowledge. I came over here and started out same kind of position, office management or office administration and permitting,” she says. “And the team here is just absolutely amazing and they taught me so much so that I grew to actually become a full on salesperson and project manager. All of us here wear a lot of hats. That’s kind of where my current title of Client Success Manager came from. I’m a project manager, but there’s a lot more to it.”

Silver

Ian Fernandez – Project Specialist

Ian Fernandez – Project Specialist

Bluebird Graphic Solutions

Ian Fernandez, 32, has been an integral part of Bluebird Graphic Solutions’ Woburn, Massachusetts-based operations since he joined the company and immediately displayed his designing and project management prowess.

“Ian is incredibly talented with his ability to imagine and make it come to life with his building and engineering skills,“ says Bluebird Graphic Solutions Business Development and Marketing manager Elena Berry. “We’re incredibly proud of Ian.”

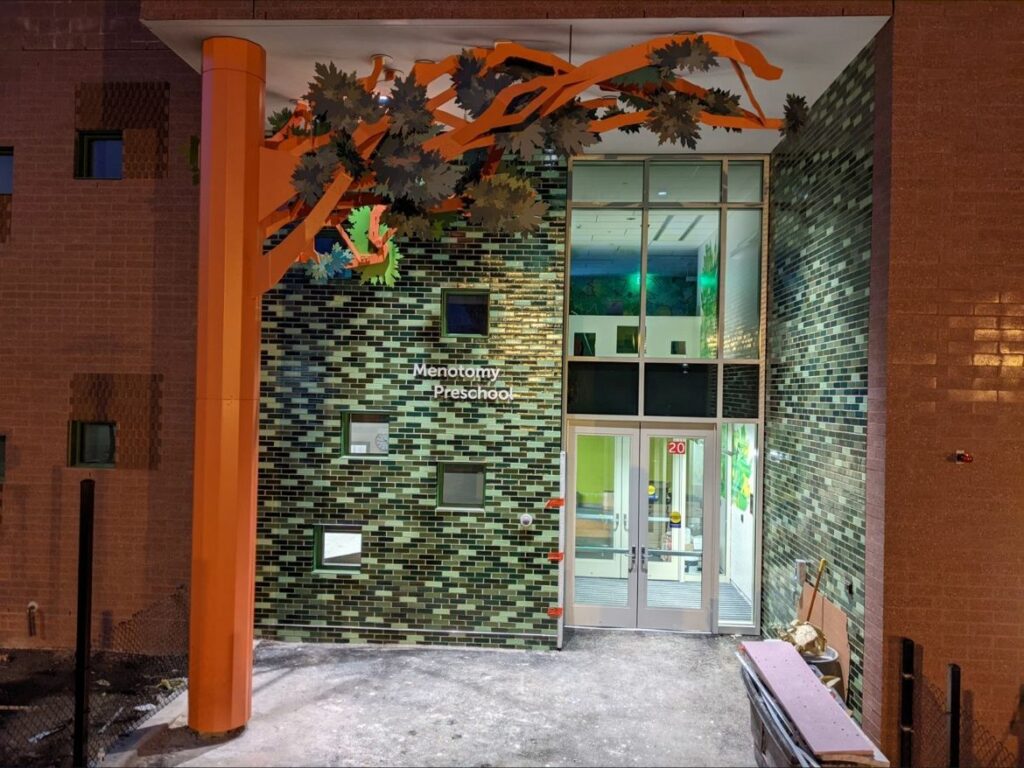

Fernandez’s involvement in the design of the Menotomy Preschool installations that centered around a tree theme.

“How I landed on the final look was an artistic whim supported by engineer problem solving. This is at a Pre-Kindergarten School so structural integrity is crucial. The first decision made was that all anchoring had to be triangulated points. With some linkage to each other or in certain groups,” says Fernandez. “The spread and design of the branches was an artistic whim; in an effort to convey a full tree canopy perceived from a kid’s perspective.”

“Several iterations took place while working with an engineer to understand the structural limitations and points of failure,” he continued. “Shapes and material choices became more clear as each area of problem turned from concept to a tangible structure.”

The key for his success may very well lie in how he views his work.

“I rarely think of what I do as signage,” says Fernandez. “I think that makes it easier to gravitate towards the more complex and unique builds that lend themselves more as sculptural work. I definitely like the big and grand.”

Fernandez’s culture plays a large role in everything he does, including his work.

“Politics aside, identity is important. I like branding while I playfully remind everyone that I do what I do because I’m Cuban. What really drives me is the hunger I get for exercising problem solving creatively,” he says. “Secondly, to do is to dare. I’m not changing the world in some dramatic way, but it would be cool to help it be more visually interesting. I find the built environment often too sterile and as an artist I’d like to help change that.”

Bronze

Jacob Bolin – Lead Fabricator

Jacob Bolin – Lead Fabricator

RiNo Sign Works

Jacob Bolin, 26, made an immediate impact at RiNo Sign Works in Denver, Colorado with his degree in Environmental Product Design from University of Colorado Boulder. Bolin brings an eye for design, problem solving skills and high craftsmanship to his role as lead fabricator at the shop.

“We are incredibly fortunate to have talented young employees like Jacob. It’s rare to find someone with his level of work ethic, dedication, and commitment to quality. He understands that exceptional craftsmanship comes from hard work and discipline, never cutting corners and always striving for perfection,” says Willis Wood, partner, RiNo Sign Works. “What truly sets Jacob apart is his willingness to speak up when something isn’t quite right or could be improved—making him an invaluable asset to our team and a game-changer in our fabrication process.”

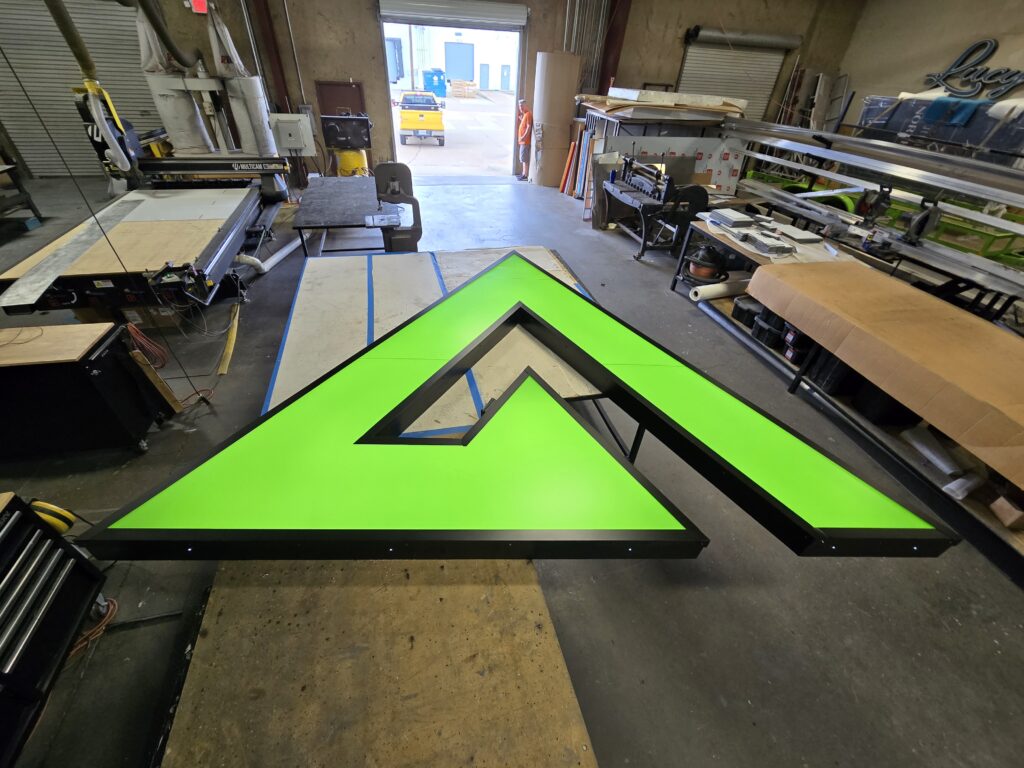

Bolin has been an integral part of many installations for RiNo, the signage package for Blue Bear Waste Services in Denver, Colorado was a perfect example of the value he brings to the company.

Bolin has been an integral part of many installations for RiNo, the signage package for Blue Bear Waste Services in Denver, Colorado was a perfect example of the value he brings to the company.

“This sign was a complex build, and Jacob played a key role in every stage of fabrication. Midway through the process, we encountered an unexpected challenge that required a completely different installation approach. Jacob was instrumental in determining the necessary modifications to enhance the sign’s structural integrity, ensuring a safe and secure installation,” says Wood. “He also meticulously ensured that the halo-illuminated channel letters and illuminated acrylic push-through letters and logos were both visually accurate and fully functional. While Jacob wasn’t directly involved in the installation, his expertise and dedication were essential to the successful fabrication of the sign.”

“Blue Bear was a bear in every way. Massive, terrifying but beautiful, and a hard fight. The sheer size, install limitations, and complex assembly all required some serious creative problem solving and a highly capable team,” says Bolin. “Fortunately, the Rino shop specializes in fighting bears!”

“Blue Bear was a bear in every way. Massive, terrifying but beautiful, and a hard fight. The sheer size, install limitations, and complex assembly all required some serious creative problem solving and a highly capable team,” says Bolin. “Fortunately, the Rino shop specializes in fighting bears!”

His special touch was also utilized in signage projects for Winter Park Resort’s Employee Housing Signage and for custom light fixtures at banks throughout the state, among other things.

“We are incredibly fortunate to have talented young employees like Jacob. It’s rare to find someone with his level of work ethic, dedication, and commitment to quality. He understands that exceptional craftsmanship comes from hard work and discipline, never cutting corners and always striving for perfection,” says Wood. “What truly sets Jacob apart is his willingness to speak up when something isn’t quite right or could be improved—making him an invaluable asset to our team and a game-changer in our fabrication process.”

Honorable Mentions

Lauren Terwilliger – Owner

Lauren Terwilliger – Owner

Pocono Sign Company

Lauren Terwilliger and her husband John started Pocono Sign Company in Lakeville, Pennsylvania, 18 years ago after a lot of perseverance, business acumen and smart decision making. They grew and emerged from COVID as a stronger company after rolling with the punches, adapting and capitalizing on trends. Now UL Certified and capable of manufacturing any and all types of signs, Pocono Sign Company is experiencing growth along the east coast after investing into their business over recent years.

“Our strategy is to become more of an East Coast manufacturing facility with expansive capabilities,” says Terwilliger. “So someone gets in, say, 30 sets of Verizon letters and they can only source 10 themselves, we’d love for them to source the rest to us.”

And a few years ago, they wouldn’t have been capable of this. But since constructing their own brand new facility by themselves and completely reworking the company since COVID, they’re poised for a great run over the coming years.

“I think we downplay ourselves just because we did start from nothing and build a really big company,” says John Terwilliger, Lauren’s husband and business partner. “Our demand has almost doubled on us post pandemic.”

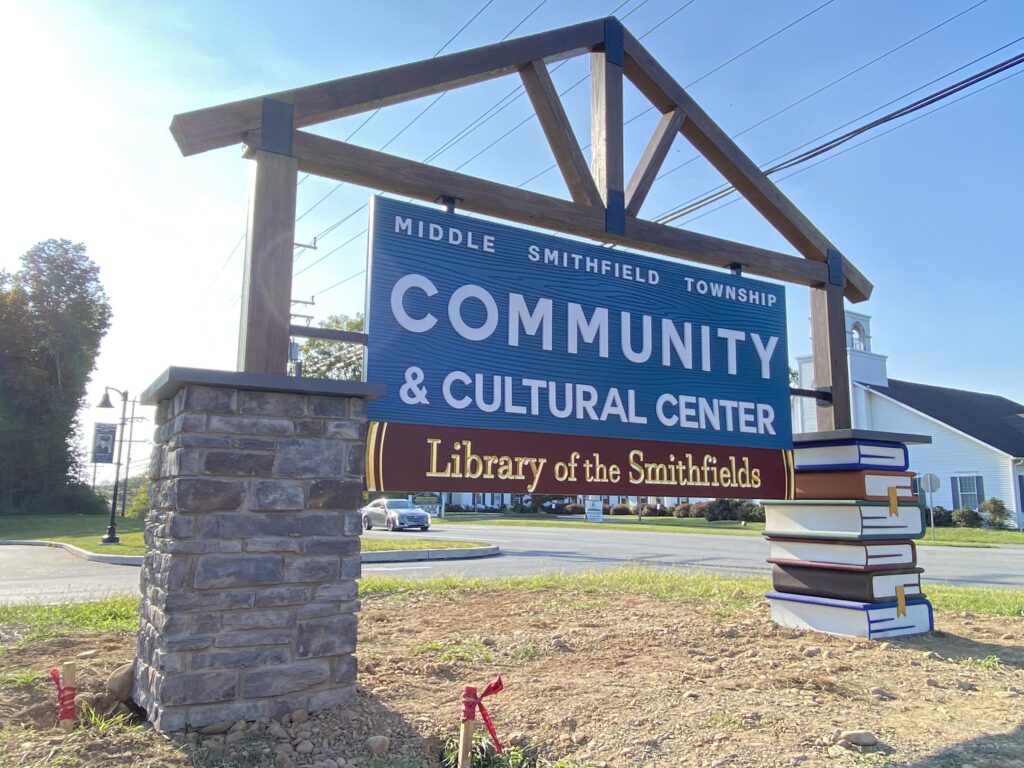

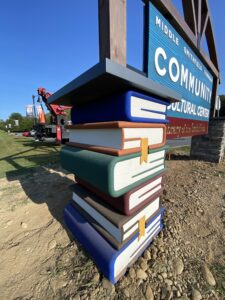

One of their most impressive installations was their work for Middle Smithfield Community College in Monroe County, Pennsylvania. The community college wanted a large sign with a unique, custom book-themed column on one side of the sign with a stone pillar on the opposite end.

One of their most impressive installations was their work for Middle Smithfield Community College in Monroe County, Pennsylvania. The community college wanted a large sign with a unique, custom book-themed column on one side of the sign with a stone pillar on the opposite end.

“They came to us with this hand drawn sketch and we sat down with them. She wanted to do something with books and she really wanted the sign centered around the library because it was such a pivotal part of the community,” says Lauren. “At that time, you know, this is five or six years ago, so we weren’t as even as developed as manufacturers then as we are now. We decided to implement the book design from Peachtree City Foamcraft to make that column of the sign really stand out. Every other aspect of that sign was done by us, from the gold letters to the other column.”

Richard Miner – Designer

Richard Miner – Designer

SignArt Inc.

Richard Miner, 39, of SignArt Inc. in Boston knows how to make any client’s dream come to life. From a vault style bank door made from car parts, to a giant HDU-crafted recycling bin, to a show-stopping golden scorpion, Miner and his team at SignArt Inc. know how to make it happen for the client.

“A lot of the cool stuff we get to do comes from a company called Big Night Entertainment Group, they own a lot of the venues and nightclubs in Boston,” says Miner. “So, they have a place called Scorpion Bar, which is of course what we made the giant gold-leaf plated, HDU scorpion for. They are also the client we made the bank vault door for.”

Now, you might ask yourself, how did they possibly route that massive golden scorpion? The answer might surprise you.

“For the big parts, like the base sections, we cut those on tabletop router. Actually, every piece was cut on the router. And then then on top of that, we assembled it and then shaped it by hand with sanders and other tools like that,” he says. “We weren’t really at the 3D level at the time. Now, I think we would 3D route the whole entire thing, layer by layer. But at the time we would just decided to shape this thing by hand.”

SignArt Inc. has been making their impression on Boston and the surrounding areas for years and years now, and Richard has been working at the company for 10 years. After building up a great reputation with large clients like Big Night Entertainment Group, the shop continues to bring in impressive projects and pump out great work.