When we asked new members of the “Behind the Signs” Facebook community what sign industry question would be most helpful to them, the top concern from installers, designers, fabricators, and owners was pricing signs.

Here are a sample of questions that we received from the group on this topic: “How do I price it all out?” “What is a reasonable rate for my products and services?” “Am I charging enough?”

The topic of pricing is a big worry for sign shops—and for good reason. Getting sign pricing right means running a profitable shop and avoiding going out of business.

Due to the many factors involved, I asked several sign shop owners and managers to share their insights regarding these questions, to help us better understand the pricing process and quoting signs.

Material Markups

Material costs alone can wipe out a job’s profitability, if not calculated correctly. So it’s important to accurately list the materials you need to complete the job and the exact cost of those materials.

Consider the type of sign, the materials required (e.g., metal, vinyl, acrylic, etc.), and any additional features (such as lighting or special finishes). Keep in mind the quality of materials, as it can impact the overall cost and durability of the sign (especially if it becomes a warranty issue later).

Markup on materials should typically be around 100 percent, excluding additional markups for potential waste.

For instance, when working with materials like acrylic sheets or other substrates, even with tightly nesting letters and shapes you will still encounter waste of approximately 10 percent or more.

Lloyd Graves, owner of Signarama Louisville, points out that materials can be marked up differently.

For example, in pricing, the markup for vinyl might be higher (around ten times the cost), whereas for ACM or aluminum, it could be lower (around three or four times). These markup rates may vary based on your particular market.

Customizable Quoting Templates

Calculating job costs involves more than just managing material expenses.

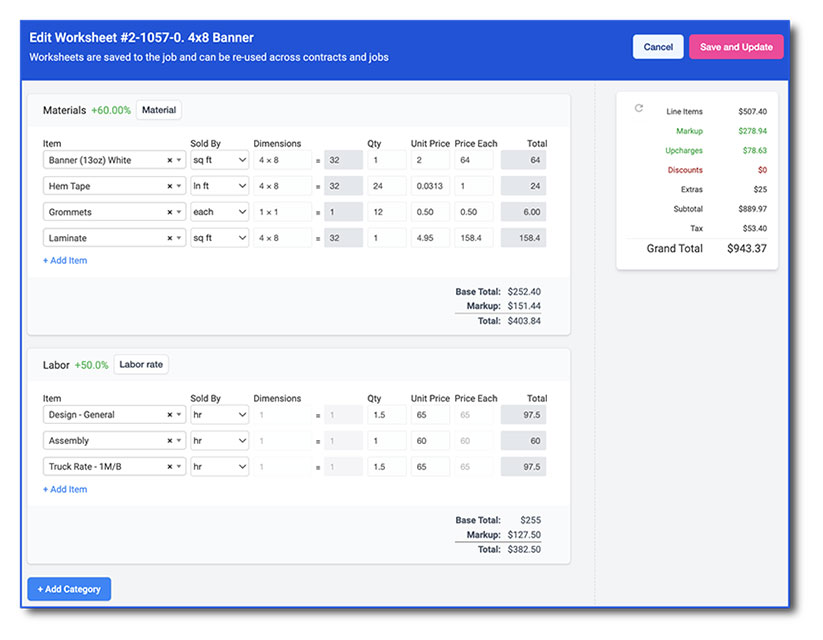

Billy Van Veghel, owner of 411 Graphic, found that accurate quoting became possible only after implementing custom quoting templates. These templates itemized all the materials used in the fabrication of various types of signs, eliminating the need to estimate costs on the fly or jot them down on paper.

Adopting a system that allows you to create customizable quoting templates tailored to your shop is crucial. Make sure the system provides the flexibility to control markups separately for materials and labor costs.

While I love SignTracker (and I confess I’m a little biased), there are several other systems available; even using tools like Excel or Google Sheets is better than not having any system in place at all.

Formula Pricing

A quick note about formula pricing for sign shops that use this quoting method: For simple signs, using square footage, upright inches, or per-piece pricing can be useful, as long as you’ve accurately calculated the cost of the formula unit and occasionally tested it.

A trick to test your formula pricing is to order a banner from a wholesale manufacturer. After you receive it, double their price then divide it by the square footage. Excluding design and admin fees, this should give you a competitive unit price.

Understanding Fabrication Materials

Understanding Fabrication Materials

Whether you’re the owner or a salesperson handling quotes for your shop, understanding how signs are made is essential.

Even if, like me, you joke about running a large sign shop without knowing how signs are actually made, there’s no escaping the need to understand materials used in the process.

I spent a good amount of time on the shop floor, talking to the fabricators and getting to know the materials used.

According to Marc Crane, operations manager at FSG Signs, new estimators at their company must work in the shop for two to three months before estimating even simple signs like vinyl graphics, flat cut letters, or basic panel signs. As they gain experience, they can gradually handle more complex and higher value projects, as long as someone continually reviews their work during this learning period.

Labor Costs and Production Time

You need to account for labor properly to avoid missing out on a lot of money.

The first thing to do when figuring out labor costs for a job is to understand your labor burden. This means considering all employee costs (like salaries, taxes, benefits, equipment, tools, and training).

The best way to calculate this is to consult with your bookkeeper or accountant to make sure you’re taking all these factors into account. You have to know the total cost of having an employee working in your company in order to be profitable. (Free Tool Alert: Go to the “Behind the Signs” Facebook community and download the free labor rate calculator from the file section.)

I often hear sign shops say they charge a flat rate of fifty dollars per hour for everything. When I ask how they decided that rate, the usual response is, “I just know I’m making money at that rate.”

It sounds simple, but it’s not. Rates should vary based on the employee’s role and the support they need to do the job right.

For example, an installer using a 100-foot crane will cost more than a graphic designer or painter in the shop. Shop owners who actually figure out the true cost of labor for the first time are often surprised to find out how low their rates are.

Christian Martinez, owner of CND Signs, began in a basic labor role at a local sign shop. Now he owns a multi-million-dollar shop with a complete fabrication facility and a fleet of trucks.

His journey involved years of hands-on work in the shop understanding the steps to build signs. Today he relies on sign engineering drawings and quoting templates to figure out the labor time required for making profitable signs.

Teaching your team to work efficiently on tasks is crucial. According to Van Veghel, employees might not be as fast as an owner/operator, but with proper training, they can come pretty darn close.

As you and your team gain more experience over time and become familiar with all the tasks involved in making and installing signs, calculating labor for projects will get easier.

Project Scope and Specifications

To safeguard your project’s profit, clearly define the project’s scope (including size, materials, and design details).

Crane emphasizes the importance of gathering all necessary information before submitting quotes to the customer. This includes a detailed site survey with photos, permit research, and any subcontractor quotes that could add cost to the job.

Once scope is clearly defined—and you understand what the client wants—get their written approval before starting the job. Track any change orders and always get them approved (even a simple email), to avoid misunderstandings and disputes later on.

Watch out for “scope creep,” where a client wants to add things not in the original contract.

According to Elizabeth Arenella-Toynes, co-owner of Studio Dzo, it’s not advisable to lower or change your contract just because a client asks. Instead suggest options like removing items for budgeting or value engineering but emphasize that the signs cost what they cost and that you can’t arbitrarily lower the price.

Protect Your Profit

Remember every company (including yours) deserves to make a profit.

When pricing a job, think beyond just one project and protect your margins across all jobs. While a big win on a single project is nice, losing money on multiple jobs can lead to financial troubles.

It’s okay to say no to jobs from clients who don’t value your work. Focus on building relationships with customers who understand your pricing, appreciate your quality, and want you to contribute to their success.

Joe Arenella founded two sign shops before launching SignTracker (an Inktavo Company). Joe is also the host of the Behind the Signs Facebook community and video podcast.