Forty years of engineering refinement gives Graphic Parts International’s (G.P.I.) Vacuum Tables their superior tooling capabilities; in-turn eliminating both your traditional clamps and custom workholding chucks. G.P.I.’s vacuum tables will save you both time and money in your machine design and fabrication efforts.

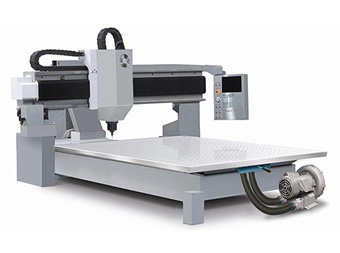

With G.P.I.’s Smart Retrofit™ workholding vacuum tables, your flat part will be held firmly and perfectly in place on your Router or Gantry style CNC machine. This makes mechanical holdown completely unnecessary. Large or small, you can machine 100 percent of your part’s exposed surface with uninterrupted passes.

By eliminating clamps and special chuck fixtures, you not only free up the machining area, but you will also have a faster set-up and take-down time. The proprietary Stay-Flat™ technology provides high-tolerance flatness and years of dependable performance. Built to last, GPI’s custom retrofit vacuum tables provide long-term functionality and versatility.

No need to buy new equipment because GPI’s vacuum tables can be engineered to fit any existing machine you have. Any size can be accommodated: up to 8 feet wide-by-25 feet long (3.1 meters wide-by-7.6 meters long). The company is expert in the retrofit of ALL brands of machining systems. Give G.P.I. your specs for any machine, and they will give you a quote that will improve your output and your bottom line.

Graphic Parts International has a reputation worldwide for “best performance” in precision work holding vacuum tables.

To find out more about GPI’s Smart Retrofit cost/time saving capabilities, call 773/725-4900, email [email protected], or visit www.vacuumtables.com/products.