Can an in-house university print provider push the “output envelope” while also making a name for itself with external customers?

As Ohio University (OU) Printing Services has proven, the answer is a definitive “yes”—that is, if it invests in the right equipment and manages to keep an ear to the ground for jobs beyond its four walls.

Nestled in the hills of Appalachia, Ohio University in Athens boasts more than a dozen schools/colleges, five regional campuses, a student population of about 28,000, and more than 4,000 employees across the state—all of which serves to keep OU Printing Services (the school’s in-house print service department) plenty busy.

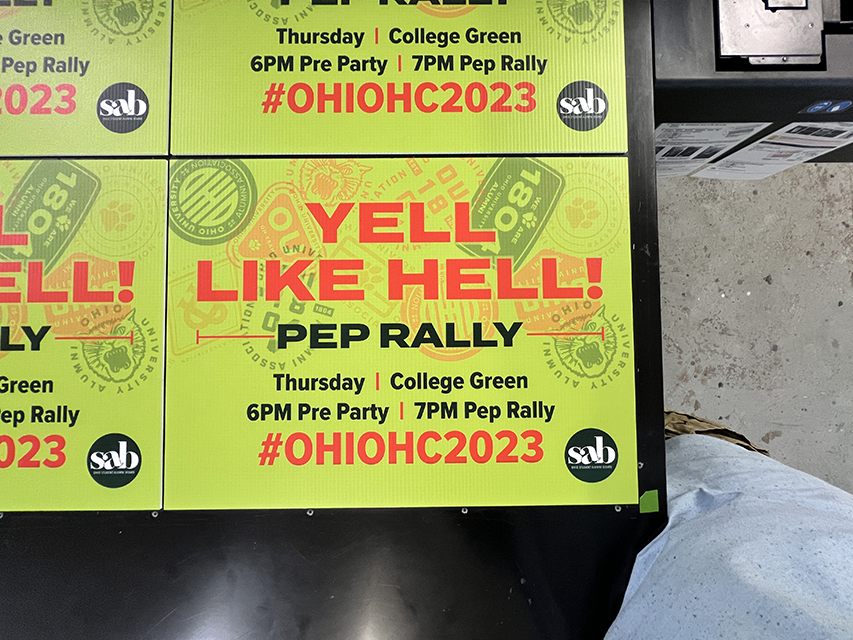

The facility produces everything from wall wraps, posters, and banners to customized apparel, table tents, business cards, and departmental stationery.

But the department doesn’t stop there. It also churns out work for the surrounding region.

In fact, OU Printing Services has become the largest printing facility in southeastern Ohio, according to Director Blaine Gabriel, and it’s managed to do so all the while continuing to provide its core university clientele with design, output, finishing, and display services.

One of the primary reasons for OU Printing Services’ rise to the top is its investment in wide format. The shop currently hosts three Mimaki wide format printers—a JFX200 UV LED flatbed, a 62-inch UCJV300-160 Plus UV roll-fed, and a 62-inch UCJV300-160 Plus solvent roll-fed.

Each of Ohio University’s five regional campuses depends on OU Printing Services for projects like wall wraps.

They utilized their Mimaki UCJV300-160 to produce messages and graphics (86-by-363 inches) onto Dreamscape Ravello Wall Wrap material for the Undergraduate Admissions office in Chubb Hall on the College Green campus. They also used their UCJV300-160 to print 107-by-324-inch wall wraps onto Dreamscape Ravello Wall Wrap media for the Main Entrance area at Ohio University Zanesville.

The Baker University Center, located near the center of the university’s main campus, is home to conference and event spaces, art galleries, a student lounge, dining options, and more. OU Printing Services printed and installed a 111-by-153-inch wall wrap for the Center’s fifth-floor lobby. They output these graphics onto Dreamscape Caviar Wall Wrap media using the Mimaki UCJV300-160.

Approximately 20 percent of the department’s work is for non-university customers. In fact, OU Printing Services employed its former Epson SureColor S80600 printer to produce a 75-by-160-inch wall mural onto DreamScape Ravello Wall Wrap with textured finish for the local IHOP restaurant.

According to Gabriel, wide format printing now makes up about 30 percent of his department’s overall work while probably about 40 percent of their wide format work goes on the flatbed. Yard signs are just one example of the many projects OU Printing Services is producing with its Mimaki JFX200 UV LED flatbed.

“More and more customers, as well as prospective customers, are starting to realize that we have the flatbed, so we’re beginning to get more and more work for it,” he says. “For example, local schools are ordering a lot of ‘big heads,’ those face-cutouts that fans hold those up during the game. Sure you can go online for them, but those typically cost nearly double what we charge for them.

“No one else in the region has a flatbed to print directly onto the substrate. They would have to output onto vinyl and then adhere it to the substrate.”

However it’s not just wide format work that accounts for the department’s success.

A second major reason for OU Printing Services’ dominance in the region is its Xerox iGen 150 color press, a digital production press that can accommodate sheet sizes up to 14.33-by-26 inches. The Xerox iGen 150 can print on coated, uncoated, textured, and specialty media—the perfect Swiss Army Knife for the facility.

Brought in-house about six years ago, the iGen 150 is, like the Mimaki flatbed, unique to the southeastern Ohio area (and perhaps West Virginia, according to Gabriel). It accounts for 40 percent of OU Printing Services’ work.

The remainder of the facility’s work breaks down this way:

Apparel: 20 percent. “We produce so many t-shirts that we’re looking at buying a new machine to make our own transfers,” says Gabriel. “We think bringing the transfer process in-house can bring our pricing down as well.”

Black-and-white toner: 5 percent. All of this is done on two Xerox D125 printers, capable of output up to 13-by-19 inches.

Engraving: 3 percent.

Signage: 2 percent. This comprises any signage not done on the Mimaki units, including ADA signage. “We install the interior signage, while the university’s Facilities department installs the exterior signage,” says Gabriel.

Something you’ll no longer find at OU Printing Services is an offset press. “We eliminated our offset technology about a year ago,” says Gabriel. “We were able to reduce costs by going all-digital and help the university with its green initiative.

“Plus, with offset, you’re limited in what you can do. We don’t really have large runs any longer. It’s mostly print on demand.”

As noted earlier, OU Printing Services has been adding more and more external clients to its workload—outside jobs now comprise about 20 percent of its work.

“We’ve been doing more work for external customers in the past fifteen years,” says Gabriel, adding that most of their external jobs are garnered via his own networking and word-of-mouth. “Because I’ve lived here my whole life, I’ve been able to make connections with various organizations in the area.

“We do work for Hocking College, Tri-County Career Center, Nelsonville York City Schools, Washington State Community College, University of Rio Grande, local photographers, and others.”

The flatbed, Gabriel points out, accounts for many of their recent external jobs.

“We have no real competition in town, especially for wide format work,” he says, “and we continue to pick up more and more of those wide format jobs as well as t-shirt work.”

More external jobs are likely available to them, says Gabriel, but he’s in the midst of re-organizing the department’s space (which is the current priority).

“Once we get everything situated in the reorganization, I might go and see if we can get some other external work,” he says. “The staff we currently have stays pretty busy. About 25 percent of our work is on one-day turnaround, which we can accommodate.”

To provide its full spectrum of services to its external (and internal) clients, OU Printing Services relies on a current staff of twelve full-timers (the director plus two prepress, one designer, two digital press, two bindery, one sign shop, one CSR, one assistant director, and one budget/admin) plus three student workers. As this article was being written, Gabriel was finalizing the addition of a thirteenth full-timer to his staff roster.

Clearly Gabriel and Ohio University Printing Services aren’t standing still when it comes to technology, services, or additional work they can take on.

In February of this year, the university print provider added an iJetColor 1175 Pro envelope press, which can do more than just envelopes—it’s capable of printing on substrates up to thirteen inches wide and full bleed.

Gabriel indicates they’re also looking at the possible addition of a wide format cutter to augment the Mimaki flatbed, in addition to the previously mentioned transfer machine to bolster their t-shirt production.

“We now do 95 percent of all our jobs on-site,” he says. “We still outsource some very high-run work, but everything else is done here in our shop.”

BONUS: Welcome to Building 37

When out-of-town clients visit Ohio University Printing Services for the first time, they may be surprised to learn that the department resides in one the many buildings that were once part of the Athens Lunatic Asylum.

Opened in the mid-1800s, the asylum was situated on nearly 1,000 acres, with a goal to provides its patients with a sustainable healing environment—everything from working fields for farming and ponds for boating to orchards, vegetable gardens, greenhouses, and even livestock.

By 1950, nearly 1,800 patients called the asylum home; by the 1980s the asylum population had dropped to about 200, and the last patients were transferred to other facilities in the early 1990s.

Shortly thereafter, the asylum and the property gained new life when they were transferred to Ohio University by the state in 1993. The university renovated many of the asylum’s eighty buildings for a variety of uses: research labs, cultural facilities, classrooms, and administrative and departmental offices.

Ohio University Printing Services is ensconced in Building 37, which originally housed the asylum’s laundry operation, where asylum staff diligently worked to process the laundry for all of the institution’s patients.

Greg Sharpless has been reporting on the printing industry and related technologies for more than twenty-five years.