A self-described “entrepreneurial spirit” and “problem-solving thinker,” Donnie Juntunen had a quite well-rounded background before deciding to get involved in the sign industry. He entered this segment at the age of twenty-nine, after dabbling around in bartending, BMX racing, owning other businesses, and achieving a college degree in sustainable business and audio/video creation.

His arrival into the sign market was eleven years ago, and the good news is that he has flourished ever since.

Juntunen is the owner of SignDog in Puyallup, Washington. It was while BMX racing over a decade ago that he met then-owner Brad Moore. “He had opened the original SignDog in Ellensburg, Washington and had been running it for nine years when I met him,” says Juntunen. “Brad was travelling often over the mountains to the Seattle/Tacoma area to race bikes, and I asked him if he’d be interested in going into business together in my area.

“We opened SignDog in Puyallup in March 2012 and [ran it] together until middle of 2015.”

At that time, Moore had decided to move several hours away to open his own shop, so Juntunen purchased his shares outright, as well as the sole rights to the SignDog name, colors, and website domain.

Five full-time employees and one part-timer make up the current SignDog Puyallup staff. Juntunen notes that he contracts an installer for their electrical signage work.

“We like to tell people that we specialize in ‘signs on walls and stickers on cars,’” remarks Juntunen.

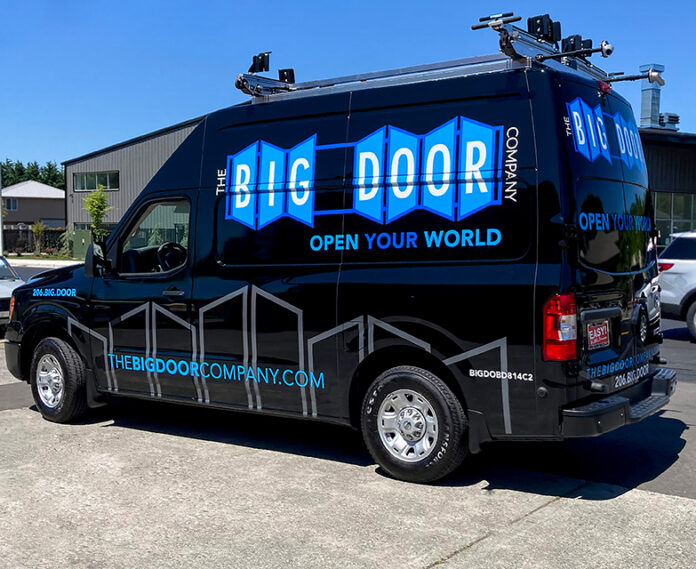

Well that phrase can be expanded upon, as SignDog Puyallup does everything from exterior and interior signage (including directional signage and yard signs) to fleet and vehicle graphics (including lettering and partial and full wraps). “And, of course, we do window graphics, wall murals, banners, and decals,” says Juntunen.

Today SignDog is located in a two-story, 3,400-square-foot facility with 2,400 square feet on the ground floor housing the lobby area, offices, and two vehicle wrap bays large enough to fit vehicles up to 35-feet-long.

The remaining 1,000 square feet is a mezzanine upstairs, which is where all the production takes place. This production area features a 64-inch Roland VersaCAMM, a 54-inch TrueVIS VG2-540, and a 54-inch TrueVIS VG3-540.

The sign shop’s big market is definitely vehicle wraps. “Our vehicle wraps business has doubled and accounts for at least 50 percent of our sales now,” comments Juntunen, “versus about 25 percent a few years ago.”

SignDog only deals with small- and medium-sized businesses, opting to refer any customers requesting personal color change-out jobs to other shops. In fact, the company mostly wraps fleet vehicles, with the occasional food truck or trailer sprinkled throughout their job orders.

“We prefer that our work helps our clients make money for their businesses,” says Juntunen, noting his company doesn’t wrap any motorcycles and rarely any boats.

Focusing on B2B clients has proven beneficial for SignDog. “This has allowed us to schedule better, set up files easier, and be more profitable with the time allowed during the day,” explains Juntunen. “Less headache/pickiness/warranties are needed when our customers aren’t ‘emotionally’ attached to the wrap the way a personal project is.”

Juntunen has found that his customers today are moving more towards full wraps as opposed to lettering or partial wraps. A reason for this is because SignDog’s customers aren’t start-ups, which according to Juntunen, means that cost isn’t necessarily standing in the way.

“Also our customers—and those of other shops—are seeing the cost benefit of the space they have on the vehicles,” he adds. “They’re seeing their competitors doing it, so they feel the need to keep up as well.”

Juntunen says the preference for full wraps is also driven by the companies they work with seeing the value of a billboard driving down the street.

“If Company A in the HVAC industry is wrapping their vans with bright, new branding, Company B feels compelled to keep up their appearance as well,” he explains. “Another bonus is many companies can put the cost of their wrap into their financing with the company they are purchasing/leasing from, so that takes the upfront cost out of the picture as well.”

Another factor is that demand of commercial vehicles is at an all-time high; this can sometimes mean that companies have to buy non-white vans, as those are in stock quicker than white vehicles. “Sometimes these colors don’t go with their branding, so we wrap them entirely,” says Juntunen.

They have a list of essential tools that help them complete vehicle wrap projects—NT Cutter blades/blade holders, medium-firm squeegees with banana felt buffers, and RollePro rollers. “We also have an array of heat guns—from Steinel professional to the Proheat appliance ones,” states Juntunen, noting the latter are long-lasting.

Other tools SignDog uses include high-pressure air-blowing tools to spray off debris and water, roller tools for rivets, denatured alcohol, WrapGlove® Ghost™, and various pick and tuck tools. “We have a scissor lift in-house as well, which helps speed up the process,” says Juntunen.

When asked if there are certain types or styles of vehicles his shop finds more challenging to wrap, Juntunen responds that any box truck with a “funky” bubble front can be “more annoying” and take more vinyl then necessary, while it can be challenging to set up files without seams on semi-truck fronts. “The time spent on the curvature is not cost friendly compared to a sprinter van, box truck, or any other commercial vehicle,” he explains.

Juntunen states though that all tough wrap projects can be either altered or avoided altogether by starting out with a good design. “We try to design to fit the mediums better,” he says, noting that part will dictate the rest. “We also set timelines that are reasonable for our customers on certain jobs that are a little more difficult.”

We’ve reported how wall murals are attracting attention, but personally, Juntunen finds these type of jobs to be “bug-a-boos,” as the surfaces can be widely inconsistent mediums (even flat walls).

“They’re such a great thing to add to spaces, and we believe they are the future more than they’re currently being used,” he says. “However paint issues and chemical reactions have made doing wall wraps aggravating. I’d love to just see a wall, measure it, design, print, and install the way we can with say a box truck, but they’re never that easy simply because of the paint used.”

Another thing with wall wraps Juntunen has found is that removable wall material can be too inconsistent, leading to re-dos no matter the prep work undertaken. “I’m eager to see someone come out with a product that is the reliable one that will work anywhere no matter what,” he says. “We would pay for that peace of mind.”

Juntunen recognizes that other sign shops provide the same type of products as SignDog offers, which has meant really reinforcing the extras that they successfully provide.

“We try to excel in our approach, our production quality, our humor, our communications, and in being ‘authentic’ all the way around,” he explains. “We pride ourselves on being responsive and creative, with state-of-the-art production equipment.

“We always deliver on time, and we make the whole process as smooth and easy as possible by asking the right questions up front and trying to see the hurdles before they’re there.”

Juntunen has big plans for SignDog going forward. For instance, he would like to open another shop in the U.S. Southwest region. “We’d like to double the staff, continue our growth in vehicle wraps, and expand our business into the construction and residential living industry, including the production of ADA signage and apartment/building signage packages,” he adds. “We have the team and printing equipment in place to do pretty much anything.”

—Additional reporting provided by Ginny Mumm.